|

RUIAN JG PU MACHINE COMPANY

|

with raw materail and oven shoe making machines

| Price: | 30000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Have one A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

with raw materail and oven shoe making machines

Control system:

1, With the state of the art computer controlled system to gain the machinery more efficiency and reliability.

2, Self-diagnosis, alarming and monitoring functions and multi-language alternatives.

3, Preset technical parameters.

4, Reserve electrical interface for mechanical arm

5, PID closed-loop and self-regulated injection program

6, Automatic PID temperature control

7, Emergent halt protection device.

Specifications

2tanks, capacity of each tank: 160L or 250L

Can make one color one density PU shoe sole

Characteristics:

1. Have one A tank and one B tank, can make different color and different density foaming shoe sole by mixing with A and B raw material.

2. Under different proportion of A and B raw material, can get different properties polyurethane sole material. The mix head with two needle which can work independently.

3. Heating system with electricity, make heating more fast and more efficient in power saving.

4. Self-developed PLC, with function of setting time, real-time monitoring and so on.

5. The speed of metering pump use frequency conversion control, with advantages of energy saving and keep the rotational speed when voltage instability.

Technical Parameter:

| Model | JG-802 |

| tank quantity | 2 |

| tank capacity | 250L |

| pump quantity | 2 |

| speed of pump (r/min) | 0-280 |

| precision(%) | ±0.5 |

| mix rotating speed of injection screw | 8600-10000 |

| clean the head | automatic |

| voltage | 380v |

| power | 13kw |

| output | 70k/s |

| clean quantity | 9000(r/min)>160 |

| clean the superfluous material | <25g |

| product characteristic | one color one density |

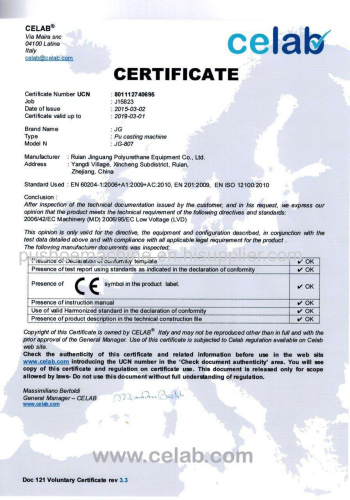

.CE

.CE

The packing and shipping

The production workshop

Attend trade shows

Our Services

Company Information

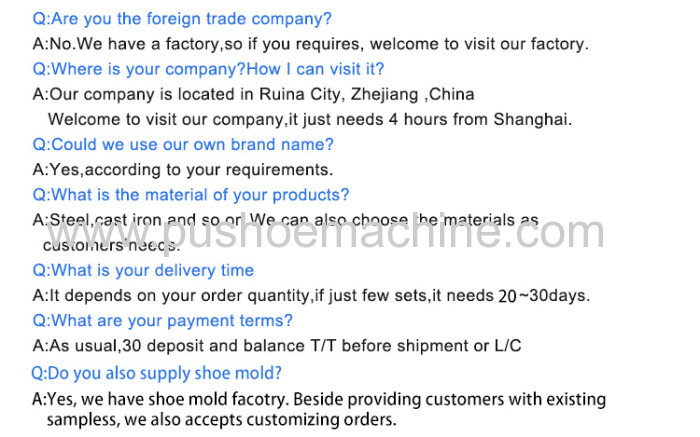

FAQ